Directory

Many people are interested in HOTROCK products. Its unique properties attract the attention of those who choose high-quality materials. Environmental safety, incombustibility, durability, exceptional thermal insulation characteristics — our customers would like to learn as much as possible about this and many other things. For this purpose, we have created this section for you.

Advantages of HOTROCK basalt insulation

Efficiency

The material provides the required level of energy efficiency of buildings and structures, significantly reducing the cost of their subsequent operation.

Eco-friendly

The material is made from natural raw materials-gabbro-basalt rocks with minimal addition of binder and without adding slags, which makes it as safe as possible for human health.

Cost-effective

Maintains a comfortable atmosphere. Protects you from unnecessary expenses for heating and cooling.

Fire resistance

The degree of combustibility of the material is NG (non-combustible). At temperatures above 1000°C, basalt slabs disintegrate, forming hot dust, without releasing harmful substances.

Durability

The material retains stable performance characteristics for 50 years.

Dimensional stability

The material retains its shape and volume throughout the entire period of operation, providing a uniform layer of insulation.

Low thermal conductivity

The material prevents the movement of heat flow, providing a comfortable temperature regime in the room at any time of the year.

Effective sound insulation

The air noise isolation index for the acoustic series is 53 dB (confirmed by the tests of NIISF RAASN).

Biological resistance

The material is not a favorable environment for the development of mold, fungi and other microorganisms. Resistant to various rodents and insects.

Easy installation

Installation does not require any special tools, it is possible to install “alone”.

- Ventilated facade system with aluminum composite panels

- Thin plaster facade system

- Thick-layer plaster facade

- Layered masonry insulation system

- Facade insulation system using siding

- Insulation of the frame wall

- Sound insulation system for partitions

- Sound insulation of floors. Floor by lags

- Floor insulation system by lags

- Insulated pitched roof system

- Cold attic pitched roof system

- Two-layer flat roof with polymer membrane on reinforced concrete slab

- Single-layer roof insulation system with bitumen waterproofing

- Double-layer flat roof with polymer membrane according to Prof.to the sheet

- Single-layer flat roof system (bitumen on a profiled sheet)

- Prefab sandwich system on a trapezoidal sheet

- Stud wall heat insulation

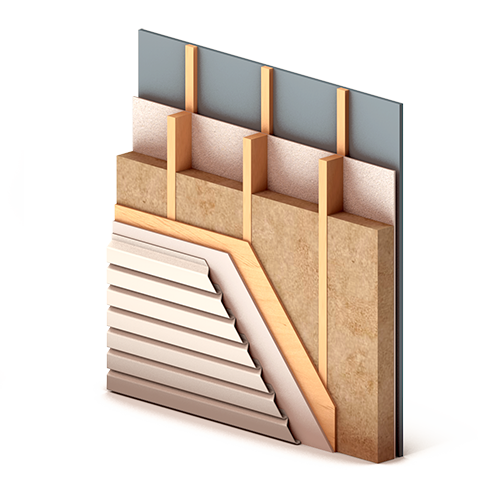

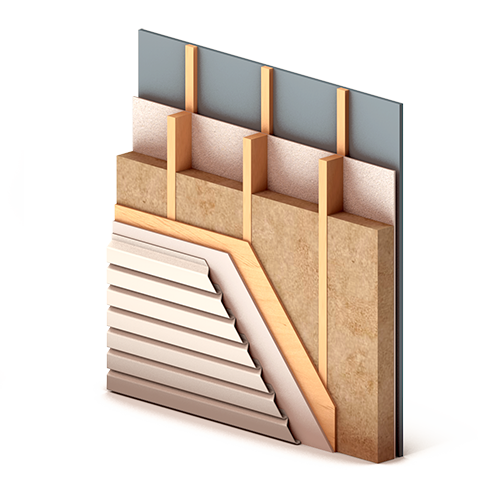

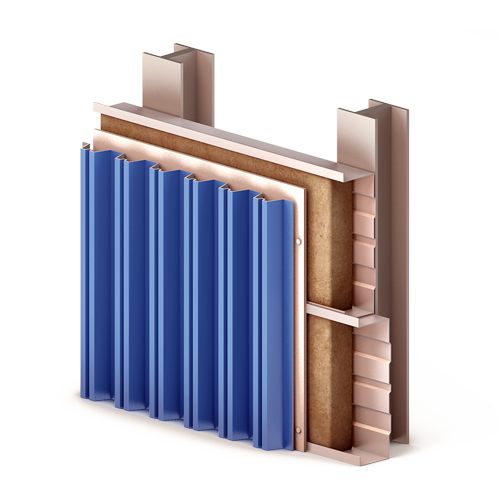

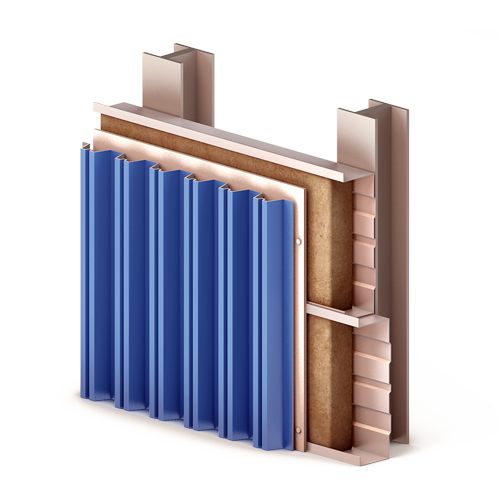

Application of HotRock thermal insulation boards made of stone wool in outdoor insulation structures with a ventilated gap for building walls

A metal frame with vertical bases is attached to the insulated wall using brackets. Between them, heat-insulating slabs made of stone wool are installed in the required number of layers. Fixing with a dowel ensures a tight fit of the material to the wall. During installation, it is important to provide a layer thickness of 5 cm for free air circulation. From above, the facade system is closed with a special plate on vertical guides.

As a heat-insulating layer in systems with a ventilated facade, it is recommended to use heat-insulating plates HotRock Vent Light, HotRock Vent Pro, HotRock Vent, HotRock Light. It is worth noting that they do not require additional devices for protection from moisture and wind.

In some cases, to reduce the load on the building structure and reduce the cost of construction, it is possible to use insulation in two layers, where plates can be used as an internal layer adjacent to the wall HotRock Light, HotRock Vent Light, with slabs as the outer layer HotRock Vent.

Ventilated facades have several advantages:

- a protective screen (protective and decorative coating) made of sheet or piece materials protects the insulation from mechanical damage, precipitation, wind and solar radiation. Improves the appearance and facilitates the performance of work during the repair of thermal insulation of enclosing structures;

- the ventilated gap eliminates the accumulation of moisture in the structure, which contributes to both increasing its heat-protective properties and durability, improving the temperature and humidity regime of premises;

- the insulation design with a protective screen allows construction and repair work to be carried out all year round. At the same time, the degree of industrialization of construction and installation works on building insulation increases, and labor costs during construction and repair are reduced;

- no pre-alignment of the load-bearing wall is required.

- glue and other “wet” processes are excluded, since all structural elements are attached and connected mechanically:

- long-term maintenance-free operation.

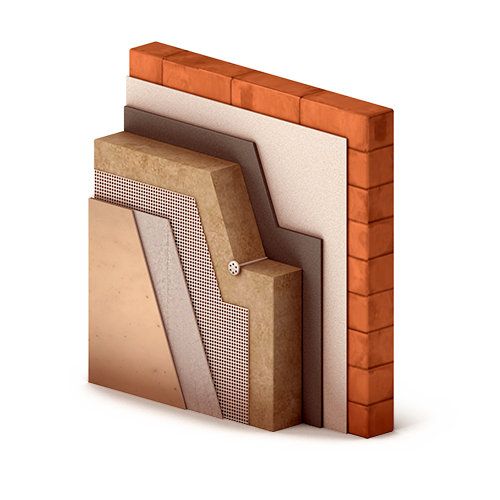

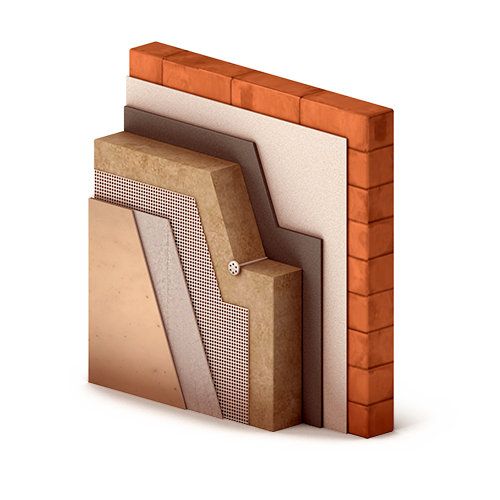

Systems of external insulation of facades of “wet” type with thin plaster consist of several successive layers: insulation attached to the supporting structure, reinforcing mesh and one or more layers of plaster

What does the facade structure consist of

Basalt thermal insulation is used as the main insulation of the building. These materials are absolutely harmless to humans, non-flammable and do not shrink over time. In addition, the boards have good sound insulation properties and provide air circulation.

Almost all types of walls made of brick or monolithic reinforced concrete are used as the basis for the system. Thermal insulation boards are attached to the facade of the building using a special construction adhesive Hotrock FACADE or Hotrock FACADE LIGHT. To increase the reliability and performance of the insulation is additionally mounted mechanically, dowels.

To strengthen the facade system, it is covered on top with a special reinforced mesh. This prevents cracking and disintegration. During finishing, tinted decorative plaster is used, which not only gives an attractive appearance to the house, but also protects it from the effects of weather conditions.

Advantages of using a thin-layer system

The structure has a high level of steam permeability, so it can be installed on any structures. Safe and non-flammable materials are used for the facade Hotrock FACADE and Hotrock FACADE LIGHT, which is especially important when insulating the walls of educational or medical institutions. For conutructions of private housing construction, as well as low-rise buildings, you can use the material Hotrock FACADE PRO.

The system creates a high level of stability of the indoor microclimate. It has one of the best degrees of uniformity.

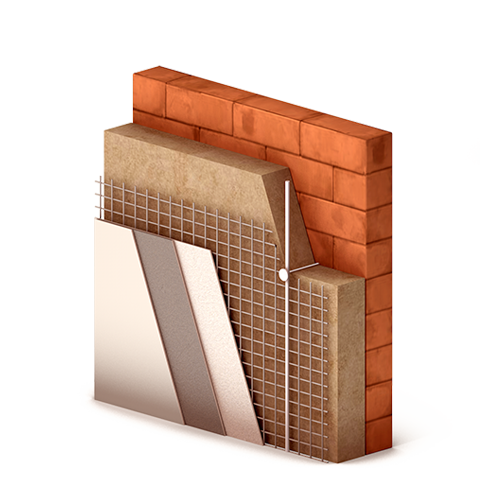

Exterior facade insulation systems with a rigid plate fastening system and traditional (thick-layer) plaster consist of several successive layers: insulation attached to the load-bearing structure, reinforcing mesh and one or more layers of plaster

What does the facade structure consist of

The solid thick-layer facade consists of decorative plaster, levelling and priming layers, steel mesh, metal anchor fasteners, exterior wall, facade paint and basalt insulation.HOTROCK FACADE or HOTROCK FACADE LIGHT. This system is perfectly suitable for all buildings of any degree of fire resistance and fire hazard class. However, the building height for this facade should not exceed 75 m.

For reliable and effective thermal insulation of the facade, hydrophobized thermal insulation boards are used HOTROCK FACADE, HOTROCK FACADE LIGHT, which are connected to the base with a special steel fastener.

Advantages of using the

system

Basalt thermal insulation is used as the main insulation of the building. These materials are absolutely harmless to humans, non-flammable and do not shrink over time. In addition, the boards have good sound insulation properties and provide air circulation.

Non-flammable basalt thermal insulation in this structure makes it suitable for use in gardens, schools, hospitals. The facade has a high impact strength due to a special reinforcing mesh made of steel. The thickness of the plaster layer reaches 30 mm. The system can easily be used both for the construction of new facilities and for the reconstruction of old ones. The basis of such a facade is almost any wall.

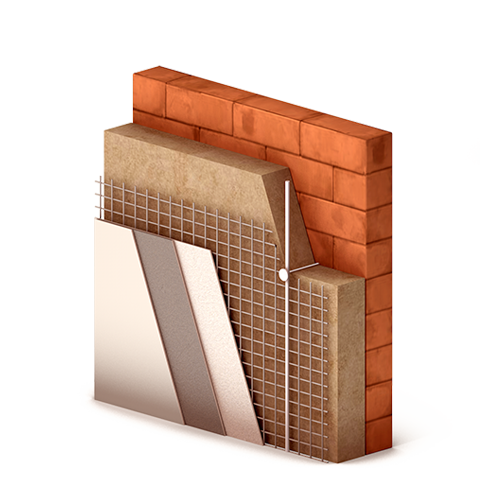

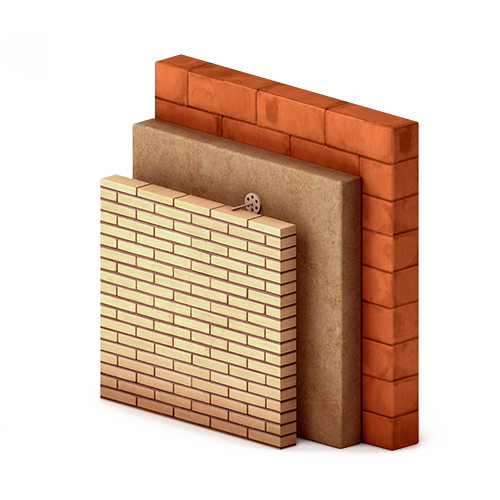

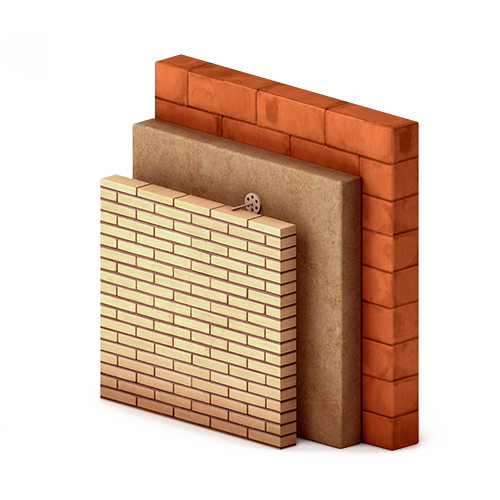

Application of HotRock thermal insulation stone wool slabs as a middle layer in three-layer wall structures with external brick cladding (other small-piece products)

Layered masonry insulation is a system consisting of a load-bearing wall, a layer of insulation and a wall made of facing material. As an external layer, brick is most often used, which, if necessary, can be additionally plastered or covered with artificial stone. One of the most common options for insulation materials is basalt insulation HOTROCK. High-quality insulation with a layer thickness determined taking into account the climatic zone will protect the house from the cold and provide sound insulation.

Insulation advantage HOTROCK BLOCK is an absolute incombustible material. The special structure of the material facilitates the installation process and provides good thermal insulation.

Presentable appearance and high durability of the structure are ensured by proper design, quality of materials used and qualified installation. The most important stage of preparation is the calculation of vapor permeability. To avoid the formation of condensation in the thickness of the structure, it is necessary to take into account the possibility of better transmission of steam by each subsequent layer, starting from the inner wall to the outside, so that there are no obstacles in the way of steam escape.

To ensure air exchange and avoid condensation, builders recommend leaving a space between the insulation and the outer wall of the order of 2 cm, as well as making a number of small holes in the lower and upper parts of the masonry.

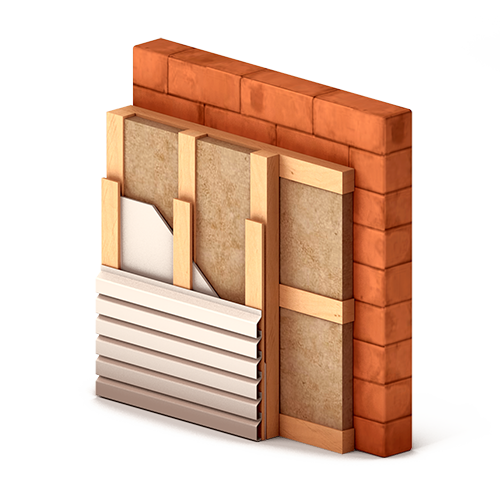

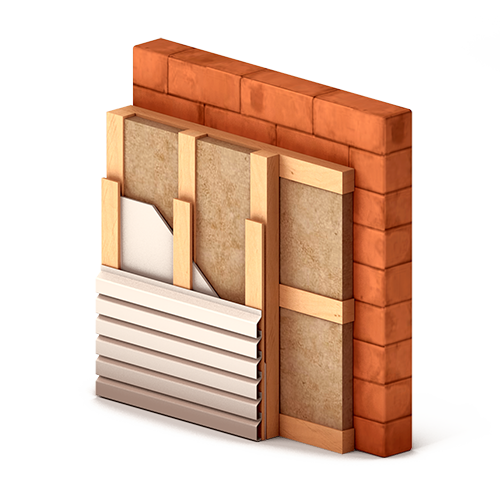

Fastening structures and materials of protective and decorative coating (facing) in systems of external insulation of buildings with a ventilated gap.

Profiled metal coatings “Ranila”, “siding” can be used for facing the facades of administrative and industrial buildings. In low-rise and cottage construction, the most effective coatings are “siding” (metal and polymer), as well as the traditional Russian wooden “lining” or tongue-and-groove board.

Vinyl siding is a popular finishing material for a country house. The multi-layered practical facade system with siding is designed to protect the walls of buildings from destruction, significantly reduce heat loss inside the room, and increase sound insulation. Such a system can be used in the construction of new structures and for the “rehabilitation” of old buildings.

This design is based on a frame, usually made of wood, which is attached to a load-bearing wall. It is in this frame that thermal insulation boards are mounted HOTROCK VENT LIGHT (HOTROCK BLOCK, HOTROCK LIGHT), set at the top a special film is attached to the vinyl siding itself.

Exterior wall decoration is characterized by a number of advantages: quick installation, cost-effectiveness, simplicity and maintainability.

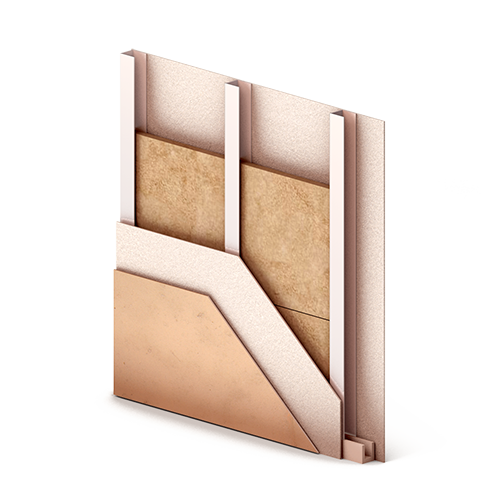

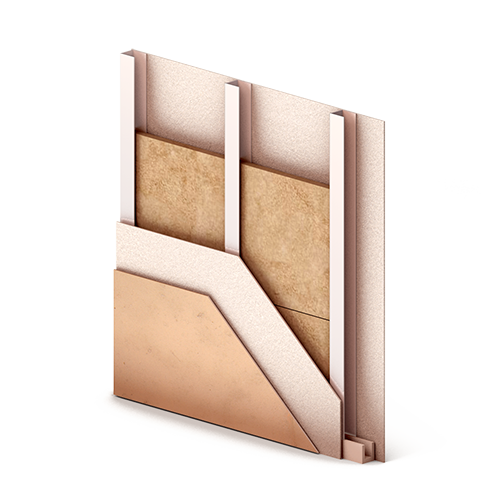

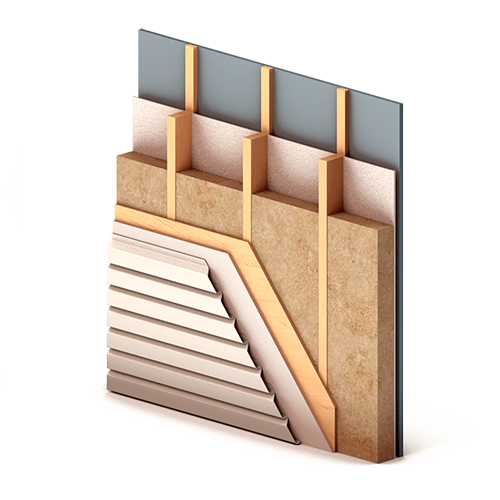

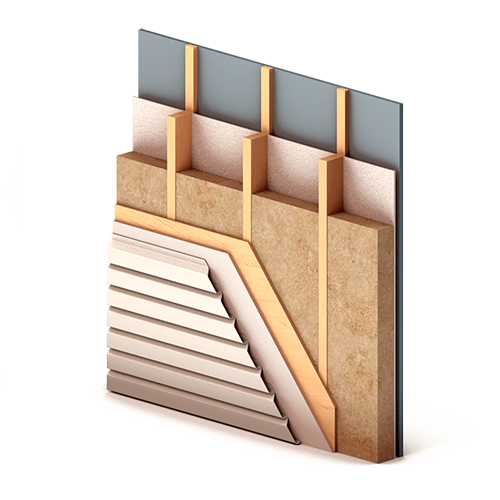

Application of HotRock stone wool slabs in frame structures of walls and timber walls in low-rise and cottage construction.

In the construction of modern townhouses, private cottages and other low-rise buildings, frame walls are increasingly being built. These structures contain a wooden or metal base with internal and external cladding. The free space inside is filled with a light stone wool insulation HOTROCK, which provides the frame with high heat and sound insulation qualities.

Among the main advantages of a modern system, it is worth noting its light weight, which allows you to save on the construction of expensive massive foundations and strong foundations. In addition, the structure can be easily and quickly assembled, without spending significant effort and time. During operation, frame systems are completely unpretentious in maintenance and are not subject to shrinkage over time.

For exterior decoration, vinyl siding is usually used, which perfectly copes with the protective function of the walls, firmly preventing the influence of natural factors.

As the most popular series of basalt insulation for frame walls, HOTROCK VENT LIGHT, HOTROCK BLOCK and HOTROCK LIGHT.

Advantages of wireframe systems

Light weight, which allows you to save on the construction of expensive massive foundations and strong foundations. The structure can be easily and quickly assembled, without spending significant effort and time. During operation, frame systems are completely unpretentious in maintenance and are not subject to shrinkage over time.

Application of stone wool slabs Hotrock as a sound insulation layer for partitions

Reliable noise protection for creating comfortable living and working conditions in buildings of any type will be provided by a special sound insulation system for walls. The main component element is a multi-layer noise-proof partition. This design is quite easy to make. For this purpose, in the production of plasterboard partitions, special basalt sound insulation plates are placed in the space between the profiles.HOTROCK ACOUSTIC. At the same time, all nodes of profile structures should be installed taking into account the recommendations of specialists.

Depending on the increase in the number of layers and thickness of partitions, the sound insulation capabilities of the system are directly proportional. Thus, thanks to the installation of such structures, the level of air noise will be significantly reduced to the required indicators.

Providing acoustic and climatic comfort is a trend of recent years. Innovative materials HOTROCK acoustics andHOTROCK flor allow you to easily and effectively create a unique atmosphere in any room, whether it’s a home theater, bedroom or study.

Application of stone wool Hotrock slabs as a sound insulation layer in non-loaded structures of light floors of interstory slabs, as well as for additional insulation.

Floor coverings are structures that not only separate floors, but also provide acoustic comfort by eliminating noise from neighboring levels.

That is why they are subject to high requirements for sound insulation.

Achieving maximum results is ensured by using acoustic design and sound-absorbing material HOTROCK ACOUSTIC.

The simplest and most reliable structure for sound insulation of floors is the following:

reinforced concrete slab, floor covering, solid fiberboard, sound insulation sheet, sealing tape. These materials are connected together mechanically. Using sound-proofing materials in this technology HOTROCK ACOUSTIC provides a comfortable microclimate in which unnecessary sounds will not irritate those who are in the room.

Insulation of inter-storey floors with a floor arrangement along lags.

If the upper floor does not have heating systems, for example, a summer veranda, then the inter-floor ceiling will act as the only protection against heat losses. To solve such problems, use the lightest plates that will not experience loads: HOTROCK LIGHT (HOTROCK LIGHT ECO), HOTROCK BLOCK. It is worth noting that the least effect will be in the case of the same microclimate indicators in two residential premises. Then basalt wool slabs will act as a sound-proofing material. They absorb noise between floors, which makes living more comfortable.

Application of HotRock stone wool slabs in non-load-bearing structures for pitched roofs

The pitched roof is supported by a special structure consisting of a crate that directly supports the roof covering, and rafters that transmit the load from the roof’s own weight, snow, wind, etc.to the walls and internal supports. Insulation of the pitched roof makes it possible to install an additional attic or attic room under it.

Insulation of pitched roofs allows you to turn the attic room into a residential one, which increases the useful area of housing, and insulation of the roof from metal profiled flooring prevents condensation on its surface in the cold season and overheating of the room in the summer.

To create an optimal microclimate and optimize the area in buildings of any type, it is necessary to carefully consider how to design and insulate the roof as efficiently as possible, as well as expand the space of your attic. Installation of a pitched roof system involves the presence of certain structural components, each of which has a different function, which significantly improves the living conditions in the premises. One of the mandatory tasks when installing a roof, especially for attic rooms, is its insulation. This is necessary to increase energy saving indicators, reduce the cost of paying for heating and air conditioning. Non-flammable thermal insulation boards HOTROCK LIGHT (HOTROCK LIGHT ECO), HOTROCK BLOCK have high technical characteristics.

They do not weigh down the structure, are noise-proof, and are easy to install.

Thermal insulation of attic floors of buildings allows you to provide a favorable indoor microclimate by increasing the temperature of the internal surface of the ceiling (ceiling or floor)and reducing the temperature difference between the internal air and the internal surface of the fence.

One of the most common ways to insulate the roof of a private house is to insulate the attic floor. The so – called cold attic. This method is the simplest and fastest. Thermal insulation HOTROCK LIGHT, HOTROCK LIGHT ECO, HOTROCK BLOCK is simply placed on the attic floor on a pre-laid vapor barrier film, which protects the insulation from waterlogging and condensation.

The heat-protective qualities of the attic floor should exclude significant heat loss and condensation of moisture on the ceiling in winter and overheating of the premises in summer.

Since the air movement in the attic is scanty, it is not necessary to additionally mount a wind shield on top of the HOTROK insulation. It is important to observe the following nuances: create a fifty-millimeter ventilation gap around the perimeter of the attic, indent. Such a measure will ensure effective air removal from the cornices. The total thickness and amount of material is calculated based on thermal engineering calculations. The use of the cold attic pitched roof system together with other energy-saving technological solutions can significantly reduce the consumption of electric energy and reduce the cost of heating/cooling the building.

When constructing a “flat roof”, the material HOTROCK RUF N and HOTROCK RUF V. Among the advantages of HOTROCK materials: simplicity, accessibility, safety, high speed of installation. The technology is based on the use of a common system of laying a less dense lower layer and a dense upper layer of thermal insulation. The moisture-tightness of the roof is ensured here by using modern polymer rolled materials, usually using a PVC membrane.

Roof construction

Roofing insulation consists of several layers of both vapor barrier and waterproofing materials. The first, lowest layer is a substrate for vapor barrier. It is laid directly on the concrete base. Next, basalt wool is used HOTROCK RUF N , which retains its integrity during fluctuations in the construction structure at the time of its subsidence.

Initially, the lower layer is laid with a low density.

A dense thin slab of basalt insulation is placed on top of the lower insulation layer HOTROCK RUF V. It takes on the load that occurs during the movement of people who install and maintain the bitumen roof.

Application

Use of basalt insulation materials in double-layer flat roof systems HOTROCK RUF N and HOTROCK RUF V has become the image of a new approach to thermal insulation. Their use in conjunction with other technological solutions can significantly reduce energy consumption for heating the building, and the ease of installation to ensure a high-quality result in the shortest possible time.

Insulation of a flat roof can be carried out not only with the help of two-layer systems, but also in one layer. For this purpose, a slab insulation is used HOTROCK RUF S. It serves as a supporting base here and can withstand not only snow loads but also the pressure exerted by moving people on the roof. A profiled sheet can also act as a supporting base. A vapor barrier film must first be placed on it. It prevents the insulation material from being moistened by steam coming from the room.

This solution has its advantages. First, the process of installing the roof is accelerated. Secondly, you do not need to build a screed, wait until it hardens and dries, which also speeds up installation. Third, the absence of a screed reduces the load on the building structure.

Advantages of

System HOTROCK RUF S is designed for use in prefabricated buildings. It has excellent mechanical strength. Its total weight is small. Among the advantages, it should also be noted fast and uncomplicated installation.

HOTROCK materials for flat roofs can be laid not only on a concrete base, but also on a trapezoidal sheet.

Thermal insulation component

The flat roof system with this solution consists of two layers of heat-insulating materials HOTROCK. Lower layer that fits less directly on the trapezoidal sheet, less dense HOTROCK RUF N and the top layer is denser HOTROCK RUF V. Its task, in addition to retaining heat, also includes redistributing the external load on the lower insulation layer. Both thermal insulation layers are attached to the base of the trapezoidal sheet using a special telescopic terel fasteners.

This solution has its advantages. First, the process of installing the roof is accelerated. Secondly, you do not need to build a screed, wait until it hardens and dries, which also speeds up installation. Third, the absence of a screed reduces the load on the building structure.

Advantages of

The HOTROCK system is designed for use in prefabricated buildings. It has excellent mechanical strength and excellent thermal insulation performance. Its total weight is small. Among the advantages, it should also be noted fast and uncomplicated installation.

Insulation of a flat roof can be carried out not only with the help of two-layer systems, but also in one layer. Tile insulation is used for this purpose HOTROCK RUF S . It serves as a load-bearing surface and can withstand not only snow loads, but also the pressure exerted by moving people on the roof. The base can be a profiled sheet and reinforced concrete slabs. To prevent the insulation material from being moistened by steam coming from the room, a vapor barrier film must be placed on the base.

This solution has its advantages. First, the roof installation process is accelerated. Secondly, the cost of installing a thermal insulation layer is reduced.

Advantages of

The HOTROCK system is designed for use in prefabricated buildings. It has excellent mechanical strength and excellent thermal insulation properties. Its total weight is small. Also worth noting is the quick and uncomplicated installation.

Recently, prefabricated sandwich panels have become very popular in the construction of commercial facilities. This is the optimal solution when it is necessary to efficiently and quickly equip industrial premises, such as warehouses, hangars, pavilions and shopping complexes. They are also suitable for building car washes, factories, etc. This is an advantageous solution for the facade, since lightweight slabs are used for such structures.HOTROCK VENT LIGHT, HOTROCK BLOCK, HOTROCK LIGHT, followed by siding-facing, profiled sheet or decorative cassettes.

A special air inner layer ensures the reliability and durability of the entire system. Also, the use of the structure does not violate the rules of fire safety. Installation of the system does not require special heavy equipment, since it is made on the principle of simple assembly.

How does the facade structure work?

The basis of the entire system is a special sandwich profile. This is a three-dimensional, but thin-layer structure made of galvanized steel sheet coated with polymer. One profile is superimposed on another, and fixed to the frame of the building with dense self-tapping screws.

In the course of construction of modern townhouses, private cottages and other low-rise buildings stud walls are erected with an increasing frequency. These structures contain a wooden or metal base with inner or outer cladding. The free space inside is filled with HOTROCK – light heat insulation material made of stone wool, which provides a frame with high heat and noise insulation properties.

The light weight, which enables to save on erection of expensive massive bases and strong foundations, should be noted amongst basic advantages of the modern system. In addition, the structure can be easily and quickly assembled without making significant efforts and spending time. In the process of operation the frame systems are absolutely maintenance-friendly and are not subjected to any shrinkage in the course of time.

For an external finish they usually use the vinyl siding, which perfectly copes with a protection function of the walls, sturdily preventing the impact of natural factors.

HOTROCK VENT LIGHT, HOTROCK BLOCK and HOTROCK LIGHT are applied as the most demanded series of basalt heat insulator for stud walls.